Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Wellhead equipment and Christmas trees are critical components in oil and gas production operations. Designed to secure the wellhead, suspend downhole tubing, and seal and control the annular space, these systems also manage wellhead pressure and regulate production flow. In addition to standard functions, they support specialized operations such as acidizing, fracturing, water or gas injection, and well testing. All products are manufactured in strict compliance with API Spec 6A standards, ensuring reliability and performance in demanding field conditions.

The casing head is a fundamental component of the wellhead system. Installed at the top of the surface casing, it provides structural support and serves to suspend and seal the casing strings. As the base section of the wellhead assembly, it plays a critical role in ensuring well integrity and safe drilling operations.

The casing spool is designed to support the weight of both the intermediate and production casing strings while providing effective sealing of the annular space between casings. It also serves as a transition connection for installing blowout preventers (BOPs), tubing heads, and other upper wellhead equipment. Engineered for strength and reliability, the casing spool is a critical component for safe and efficient well control operations.

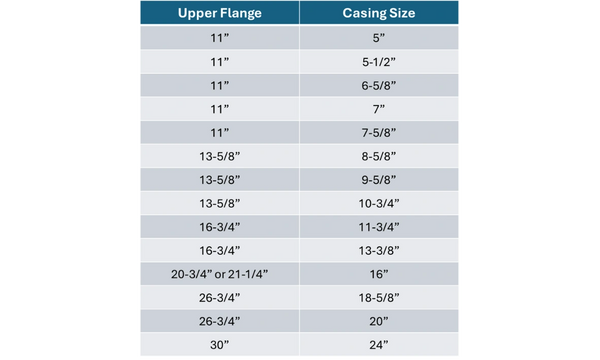

The casing hanger is installed within the upper flange bore of the casing head or casing spool. It uses wedge-shaped slip teeth to grip and suspend the casing string securely in place. Relying on the weight of the casing string, it activates the sealing mechanism to effectively isolate and seal the annular space between casing layers, ensuring a reliable pressure barrier within the wellhead system.

Installed beneath the casing head, the casing head base connects the casing head to the surface casing or conductor pipe. It utilizes external connecting bolts to apply force, enabling the slip teeth to securely grip the casing. This ensures a stable and pressure-tight foundation for the wellhead system, enhancing both operational safety and structural integrity.

Installed into the upper flange bore of a casing head or casing spool, this mechanical seal casing hanger uses wedge-style slips to generate gripping force, securely suspending the casing string. The sealing mechanism is manually activated by tightening screws, providing a dependable seal in the annular space between casing layers—ensuring operational safety and pressure integrity.

Installed into the upper flange bore of a casing head or casing spool, this hanger suspends the casing string via threaded lower casing connection. Sealing is activated by the weight of the casing and the compressive force from the set screws, ensuring reliable isolation of the annular space between casing layers.

Design Features:

The tubing head spool is a critical component installed above the uppermost casing head and below the production (oil or gas) tree. It is designed to suspend the production tubing and effectively seal the annular space between the tubing and casing. In addition to supporting downhole tools, the tubing head ensures pressure integrity and provides access for well servicing operations. Its robust construction is essential for safe and efficient wellhead performance.

Installed above the tubing head, the Christmas tree is designed to control and regulate the flow rate and wellhead pressure of oil and gas wells. It also directs the production flow to downstream pipelines for processing and transportation.

Available Configurations:

Engineered for reliability and performance, the Christmas tree is a vital component for safe and efficient well control.

The tubing hanger is designed to suspend the production tubing and seal the annular space between the tubing and casing. It connects directly to the tubing string and is seated within the tubing spool using the weight of the tubing itself, ensuring a reliable seal.

Design Features:

Engineered for performance and safety, the tubing hanger ensures dependable well integrity while supporting advanced downhole communication or control systems.

The dual tubing wellhead and production tree system is engineered for wells requiring two independent production strings, enabling enhanced operational flexibility and well control.

Key Features:

This system is ideal for maximizing output and operational efficiency in multi-zone or dual completion wells.

Designed for offshore applications, the single conductor dual wellhead and tree system supports two independent wellbores within a shared conductor, optimizing space and reducing structural complexity on marine platforms.

Key Features:

This solution is ideal for space-constrained environments like offshore platforms, delivering efficient dual-well operation within a single structural footprint.

Engineered for offshore platforms, the single conductor triple wellhead and tree system supports three independent wellbores within one shared conductor, delivering exceptional space efficiency and production flexibility in complex marine environments.

Key Features:

This compact, high-performance solution is ideal for offshore platforms aiming to maximize production capacity while minimizing infrastructure footprint.

The compact wellhead and tree system is specifically designed to reduce overall height and weight, enhancing efficiency and safety during installation and drilling operations.

Key Features:

This compact system delivers robust performance with a smaller footprint, making it an optimal solution for modern drilling and production operations.

Designed for enhanced efficiency and operational flexibility, the multi-wellhead and tree system offers a compact and robust solution for high-density well configurations.

Key Features:

This system is ideal for multi-well pad or offshore installations requiring streamlined processes and high-performance hardware.

Engineered for coiled tubing operations, this wellhead and tree system delivers secure, efficient, and modular performance tailored for continuous intervention and production.

Key Features:

Optimized for coiled tubing applications, this system ensures safe, time-efficient operations with maximum adaptability in the field.

Designed for dynamic well testing environments, the surface rotating test tree offers robust support and control for test string operations while enhancing safety and efficiency.

Key Features:

Ideal for surface well testing, this system delivers performance, convenience, and protection in a compact, integrated solution.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.